In the development of leather products like bags or accessories, sampling connects the design idea to actual production. Sampling needs clear details to ensure quality and efficiency. Many beginners or designers ask: Why do we need flat drawings or an artwo? Can reference images alone work? How can we make sampling accurate and get the desired style in one try? This article, based on multiple sources, explores this topic. With AI tools becoming popular, the process is getting faster, but flat drawings remain key. This article combines main points, highlights patterns and issues, and offers practical tips.

Core Steps in Leather Product Sampling

Leather product sampling is the process of turning designs (like handbags, wallets, or belts) into prototypes to test feasibility, optimize materials, and reduce risks in mass production. Sampling includes several steps:

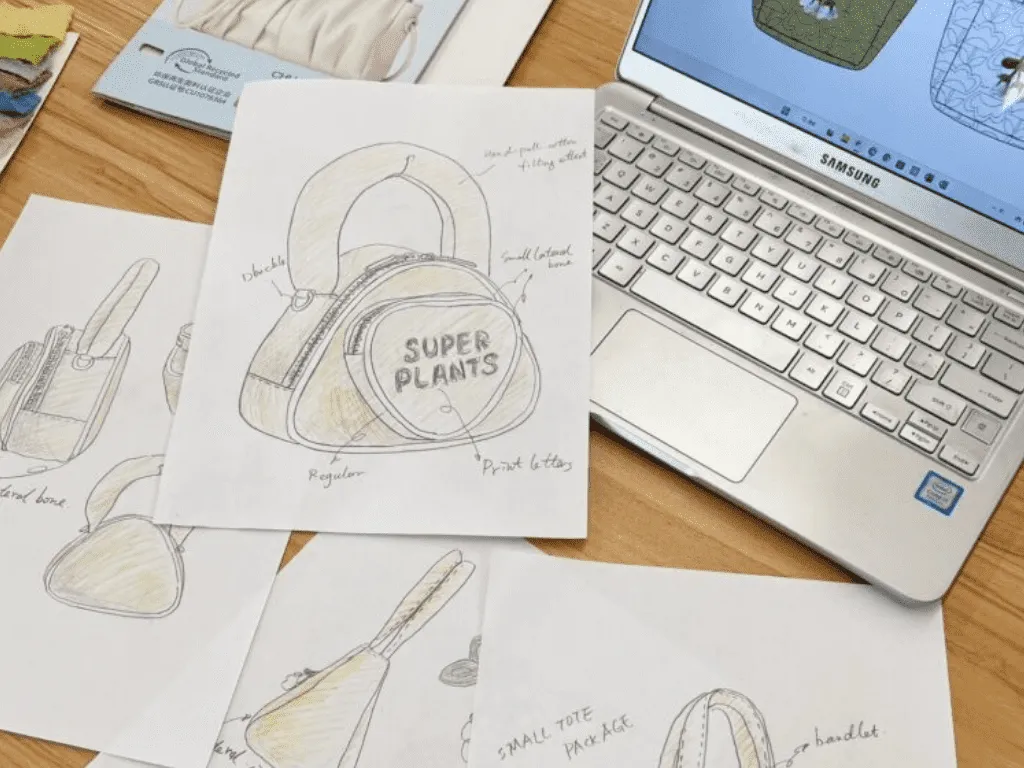

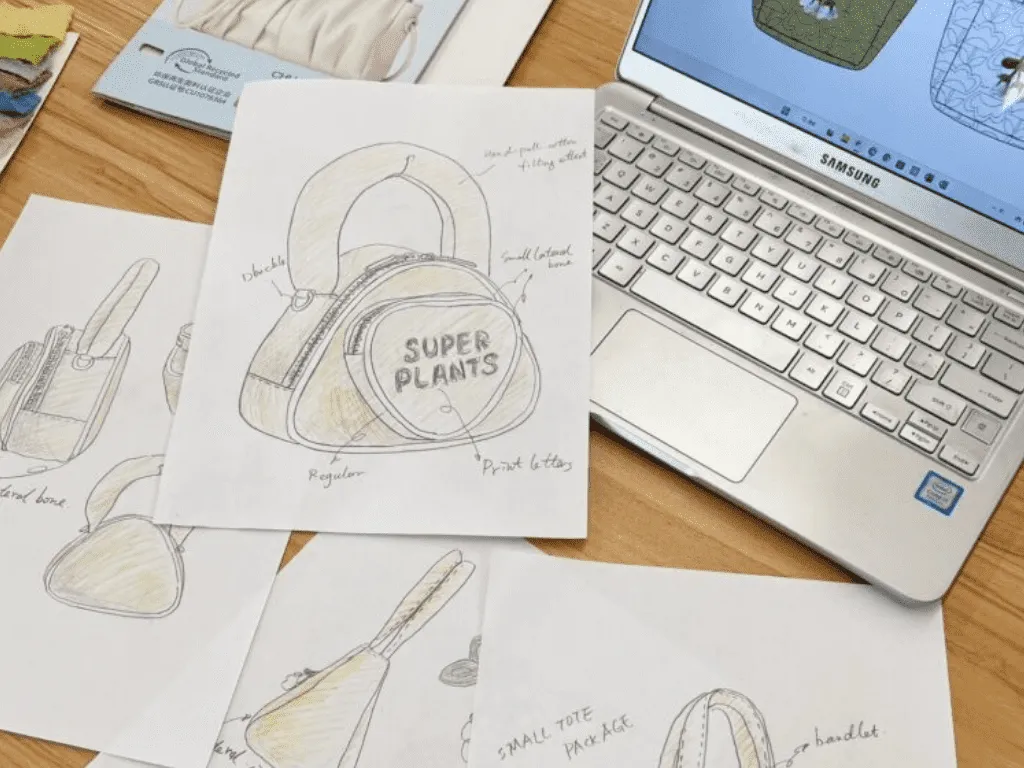

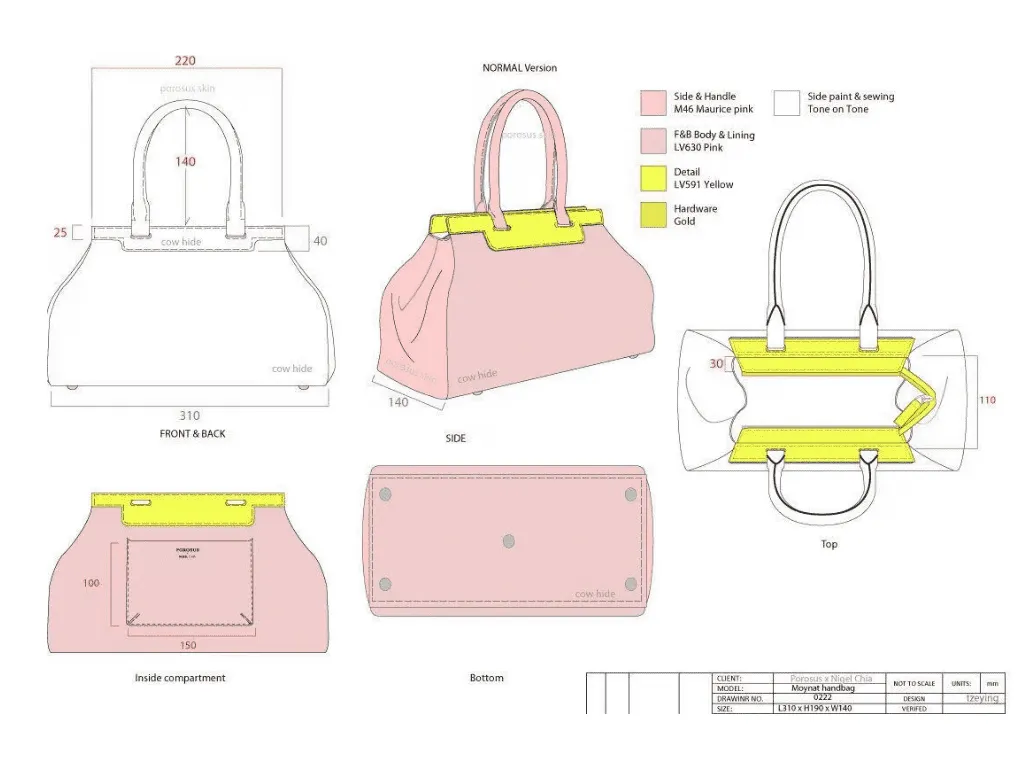

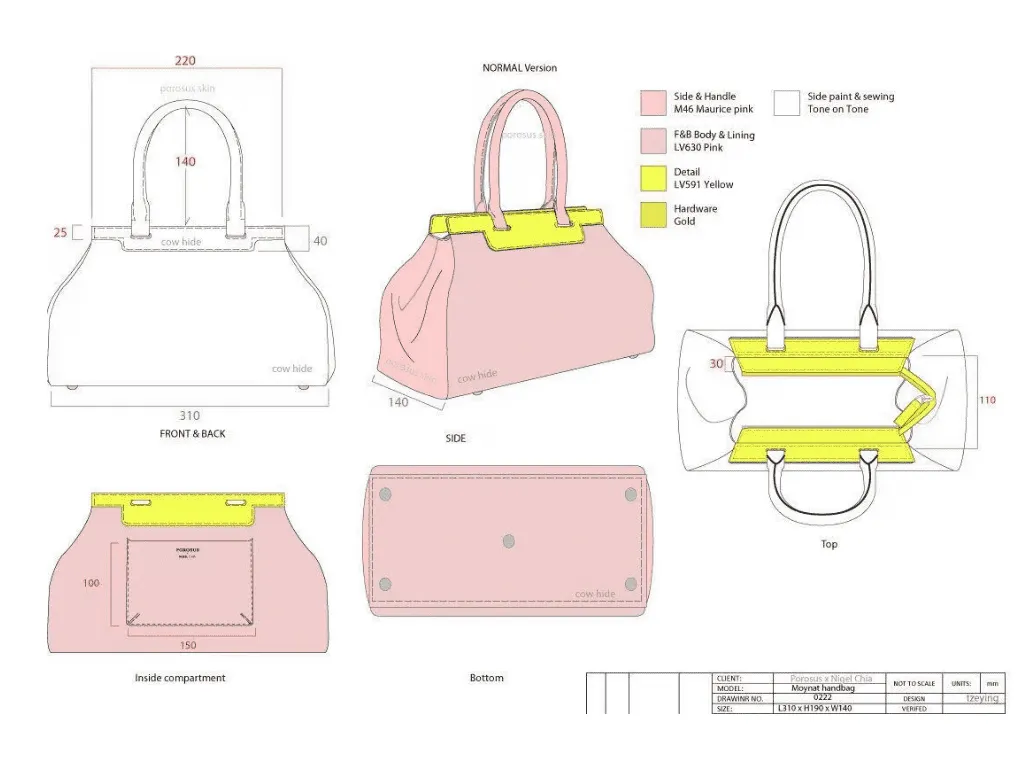

CAD Flat Drawing

After confirming details with the client, the factory translates the design into CAD drawings. These drawings are printed 1:1 on paperboard, which the artisan uses to cut materials.

Material Cutting

The artisan lays out the leather and cuts parts based on the paperboard templates. After cutting, they move to stitching and edge painting.

Edge Painting

Some parts need edge painting before stitching, depending on the product. The paint color matches the leather, is applied evenly to edges, and left to dry.

Stitching

Stitching and hardware assembly often happen together. Some hardware, like D-rings for handles, is added before stitching, while zippers are installed during stitching.

After these steps, the leather product is complete. The final step is checking if the sample’s size and shape match the client’s design.

For complex designs, factories may use PU material for a prototype to save time and avoid wasting leather. Why Start with Prototyping Before Making Leather Samples here is an article to explain why we need a mockup before using correct material.

From these steps, it’s clear that flat drawings are the basis for creating samples.

Challenges of Relying Only on Reference Images

Is it possible to make a sample with just reference images?

Yes, but it requires a very experienced artisan and very clear details from the client. It also likely means needing two or more rounds of samples to finalize the design.

Lack of Precision

Reference images show only the product’s appearance, not details like size, internal structure, or stitching. For example, a bag’s image shows its shape but not the lining or stitch spacing. If the factory guesses these details, the sample may not match the client’s vision, leading to more revisions.

Higher Communication Costs

Without flat drawings, clients and factories must communicate multiple times to clarify details. For example, clients may need to explain a part’s size or material repeatedly. This takes longer and can cause misunderstandings. Flat drawings, however, provide all information at once, saving time.

Quality Control Risks

With only images, artisans may rely on their experience or habits, leading to inconsistent quality. For instance, stitch density or leather joining may not meet expectations. This is a bigger issue for complex products like shoes or multi-layered bags, where mistakes can make samples unusable.

Limited Use Cases

For simple leather products, like flat wallets, reference images might work. But for complex items, like structured bags or boots, images can’t fully convey the design, increasing errors.

Overall, even a hand-drawn flat drawing is better than just images. Providing a physical sample is even better. This ensures high accuracy, saves time, and reduces costs.

If you have questions about leather product sampling, contact me. With 8 years in the leather handbag business, I’m ready to help.