I. Why Logos Matter

Genuine leather handbags are more than functional accessories—they tell a brand’s story. At the heart of this story is the logo, a small but powerful element that can evoke luxury, playfulness, or innovation. Why logos matter for brands?How do you turn a simple design into a standout feature? The answer lies in craftsmanship. Various logo-making techniques offer stunning style options, from subtle embossed letters exuding elegance to bold, colorful patches showing personality. These techniques not only enhance a handbag’s look but also affect its durability, cost, and market appeal.

In this article, we explore eight common handbag logo crafting techniques, based on industry practices. We’ll analyze how each creates unique logos—textured and durable, vibrant and affordable, or sleek and modern. We’ll cover their features, uses, and examples to help brands, designers, and enthusiasts choose what fits their vision. Questions like “How do I make a logo that’s eye-catching and long-lasting?” or “What’s the best option for a budget-friendly collection?” will find clear answers here.

Historically, handbag logos evolved from simple sewn labels in the early 20th century to today’s high-tech designs, reflecting changes in fashion and technology. Now, with trends like sustainability and personalization, these techniques are adapting to eco-friendly materials and custom needs. Let’s dive into how these crafts bring logos to life.

II. Understanding Different Handbag Logo Techniques

Each technique offers a unique way to create logos based on materials, design needs, and brand goals. Below, we break down eight methods, showing how they produce logos from intricate and colorful to simple and sturdy.

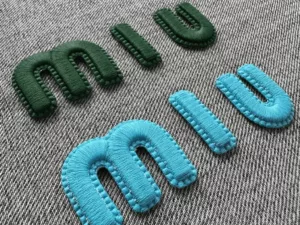

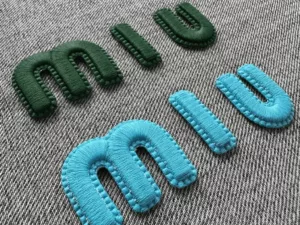

- Embroidery

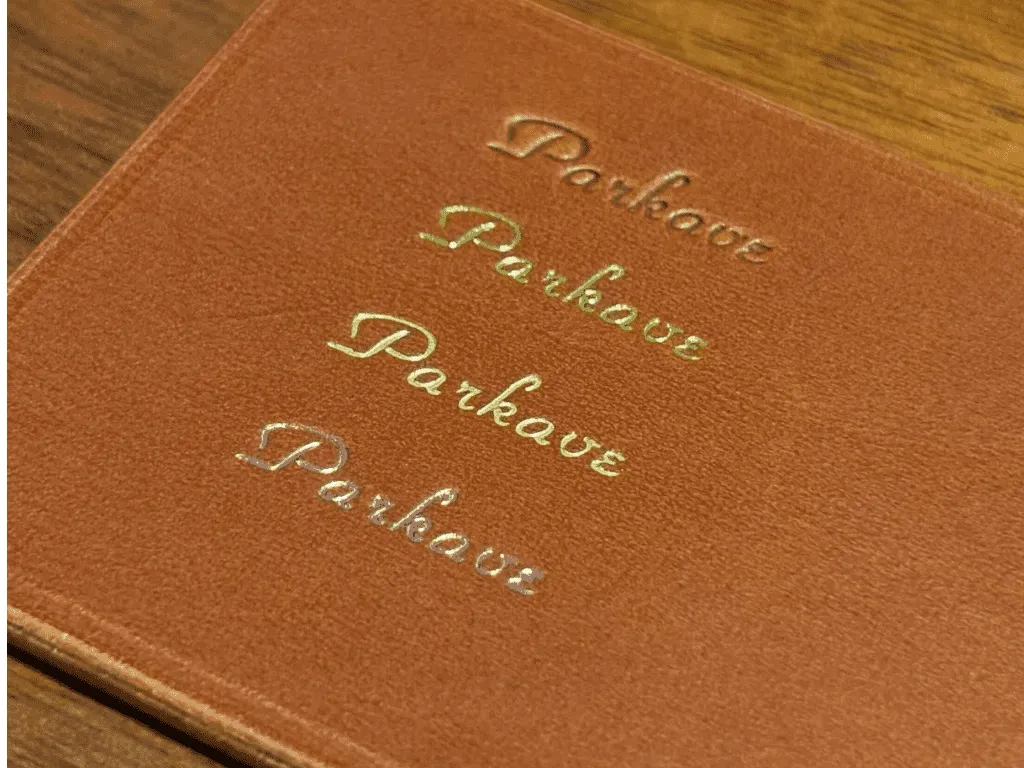

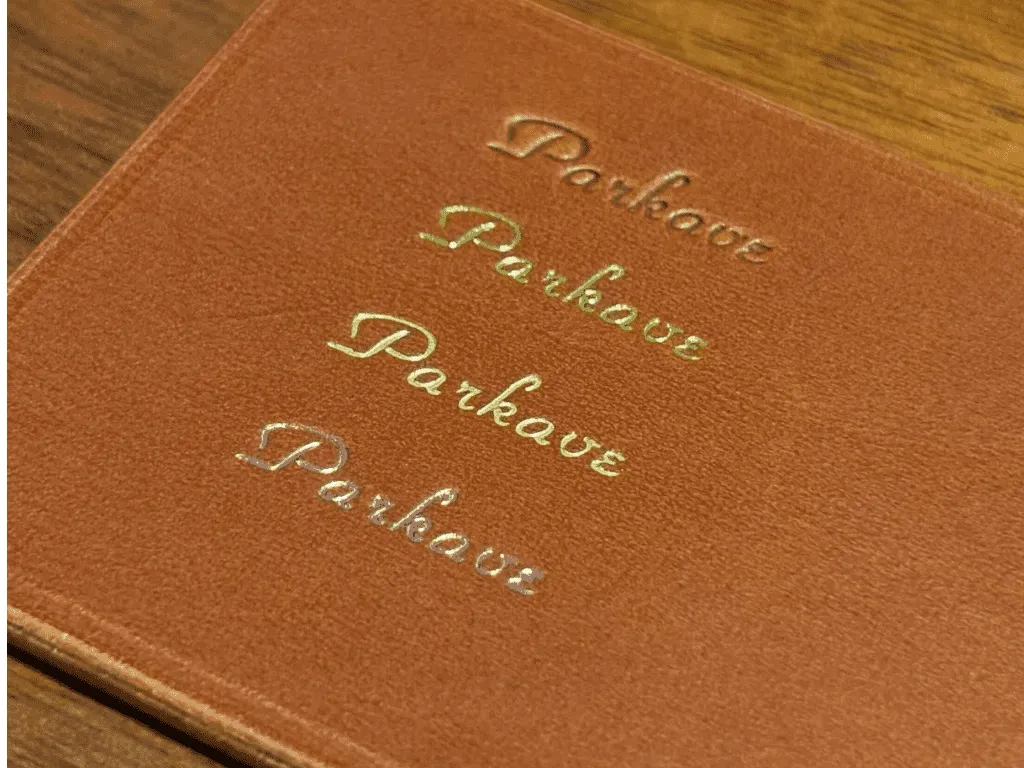

Embroidery uses needle and thread to stitch logos onto handbag fabric, creating raised, textured designs with a high-end, handcrafted feel. It excels at producing detailed, colorful logos, adding depth and personality. It works well on fabric, canvas, or leather bags. The result is durable and vibrant, ideal for classic or vintage-style brands, with intricate details like swirls or text. Typically, a computer-controlled machine stitches the logo in about 30 minutes, ensuring vibrant, precise results.Example: A colorful embroidered brand icon on a casual tote evokes timeless craftsmanship. - Heat Stamping/Embossing

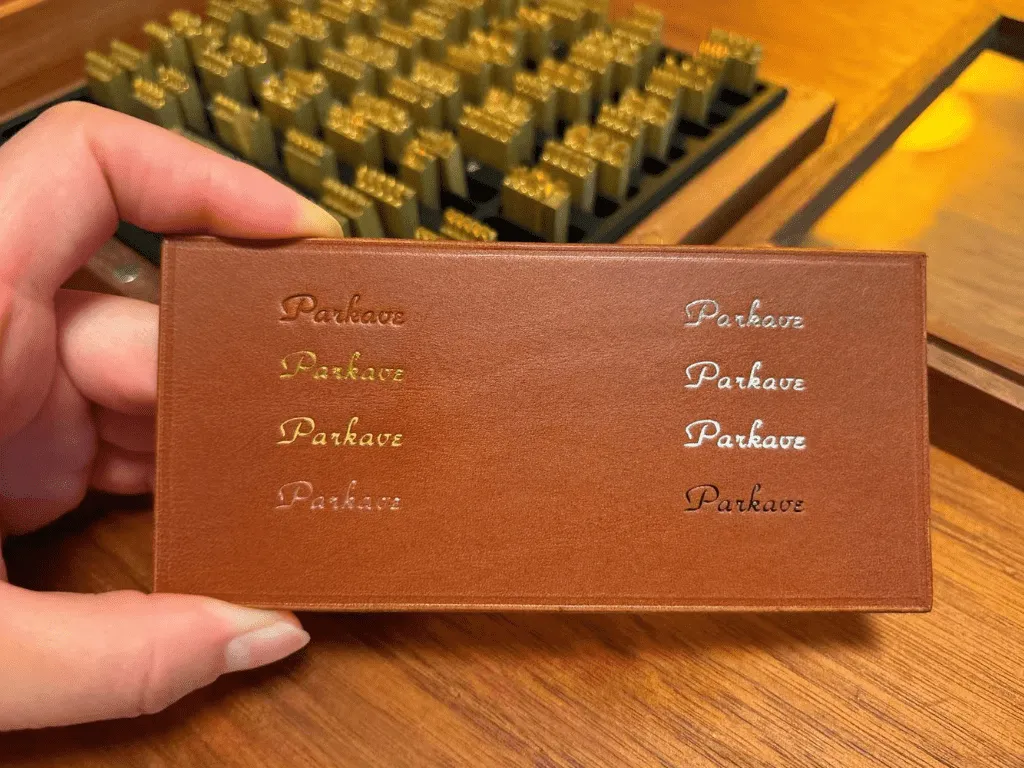

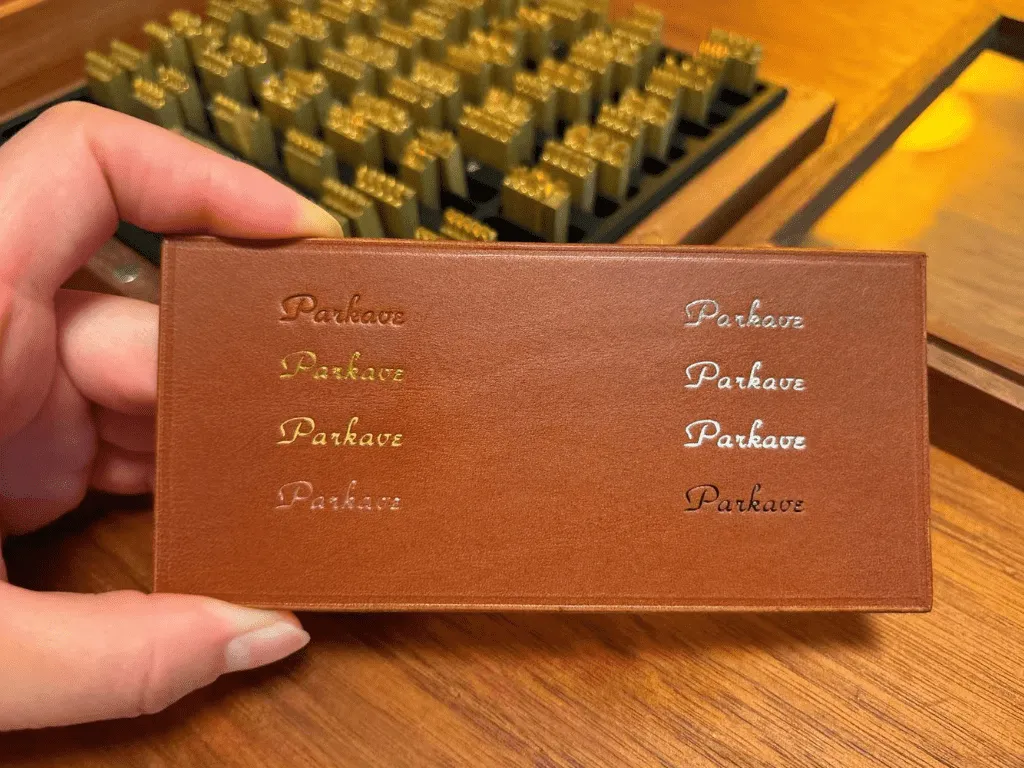

This technique uses a heated mold to press logos into leather or synthetic materials, creating a sunken or foil-covered 3D effect. It produces sleek, elegant logos—subtle without color or shiny with gold/silver foil. It’s perfect for leather bags, offering high durability and a luxurious vibe. This is a top choice for many luxury brands.Example: A minimalist gold-embossed letter on a high-end handbag symbolizes understated elegance. Designers praise its durability, noting it resists daily wear better than printed logos. - Metal Plate

Metal logos involve carving or laser-etching a brand’s design onto metal and attaching it to the bag with stitching or rivets. They create sturdy, shiny logos that exude luxury. Ideal for structured bags, they produce modern, minimalist designs with a metallic sheen that elevates the look.Example: A polished metal brand badge on a leather satchel serves as both a logo and a symbol of quality. - Screen Printing

Screen printing applies ink through a mesh to surfaces like canvas or nylon, creating bold, multi-colored, complex logos. It’s cost-effective for vibrant, large designs but may fade with washing. It’s great for creative designers, offering rich, varied effects with a slight 3D feel.Example: A cartoonish brand design on a nylon backpack or a logo on a canvas tote. It’s colorful but less suited for high-wear products. - Laser Engraving

Using precise lasers, this method etches designs into leather or metal, creating sharp, permanent logos with fine details. It produces modern, tech-savvy styles that never fade, perfect for personalized or geometric patterns.Example: A finely etched brand pattern on a leather clutch showcases a modern vibe. - Woven Labels

Woven labels involve weaving logos into fabric tags, then sewing them onto bags, offering a soft, detailed effect. They’re budget-friendly and ideal for fabric or mixed-material bags, often used on linings.Example: A colorful woven label on a canvas tote, affordable and great for mass production. - PVC/Rubber Patches

This method molds PVC or rubber into 3D logos, then attaches them, creating raised, waterproof designs. It produces playful, durable logos in bright colors, perfect for sporty or youthful bags.Example: A vibrant rubber badge on a backpack, full of energy and durability. - Digital Printing

Digital printing sprays high-resolution ink onto surfaces, allowing complex gradient patterns like photos or illustrations. It creates customizable, full-color designs, similar to screen printing but cheaper. It suits canvas or synthetics but is less durable than etching.Example: A photo-quality brand design on a limited-edition tote. With digital tech advancing, this method accounts for 10-15% of personalized designs.

Table: Quick Comparison of Techniques

| Technique | Logo Type | Best Materials | Durability | Cost Level |

|---|---|---|---|---|

| Embroidery | Textured, Colorful | Fabric/Leather | High | Medium |

| Heat Stamping | Elegant, 3D/Foil | Leather | High | Medium-High |

| Metal Plaques | Metallic, Minimalist | Structured Bags | Very High | High |

| Screen Printing | Vibrant, Multi-Color | Canvas/Nylon | Medium | Low |

| Laser Engraving | Precise, Etched | Leather/Metal | Very High | High |

| Woven Labels | Soft, Detailed | Fabric | Medium | Low |

| PVC/Rubber Patches | 3D, Playful | Casual Bags | High | Medium |

| Digital Printing | High-Resolution, Gradient | Canvas/Synthetics | Medium | Low-Medium |

III. Comparing the Techniques

These techniques reveal clear patterns: metal plaques, heat stamping, and laser engraving lean toward durable, luxurious logos for high-end brands, while screen printing, woven labels, and digital printing offer vibrant, affordable options for mass markets. The trade-off is aesthetics versus durability—screen printing’s bold colors may fade, unlike laser engraving’s permanence. A McKinsey fashion report notes durable techniques dominate 60% of the luxury market, while budget-friendly ones cover 70% of casual markets.

Experts have varied preferences: luxury brands like Hermès favor heat stamping for its timeless elegance and wear resistance, while streetwear brands like Supreme choose PVC patches for bold, youthful appeal. However, limitations exist—not every technique suits every material.

From our 20 years of industry experience, heat stamping is the choice for 80% of clients. It balances cost and beauty. A simple gold or silver logo on leather feels understated yet luxurious. Plus, it’s quick—just 10-15 seconds with a heated mold completes a stunning logo.

IV. Conclusion: Bringing It Together and Looking Ahead

Genuine leather Handbag logo techniques unlock endless possibilities, from embroidery’s textured artistry to laser engraving’s precise modernity. By balancing durability, cost, and material fit, brands can create logos that resonate with their audience. Want a unique logo? Contact us for tailored advice based on these techniques. With 20 years as a factory, we go beyond “you ask, we make.” We understand your needs and craft custom solutions. Start creating your standout logo today!