In the vast market of leather bondage products, choosing a reliable manufacturer is the cornerstone of building a successful brand. This is not just about the product’s visual appeal and lifespan; it directly impacts user safety and your brand’s long-term reputation. A great manufacturing partner can turn your designs into reality and ensure every product meets the highest standards, earning you consumer trust and long-term loyalty. This guide will provide a comprehensive framework to help you evaluate potential partners and make an informed decision. We’ll start by understanding your own needs, move on to assessing key manufacturer criteria, and finally discuss how to lock in the best partner through practical verification.

Your Product’s Positioning

Before you seek any external help, you must first have a clear understanding of your brand and products. This is the foundation of the entire selection process. Is your focus on private customization or high-end design? Both have high demands on a manufacturer, especially private customization. Private customization means the product must be completed exactly to a single client’s vision. Sometimes this may also require some design capabilities from the manufacturer.

Material Selection

Leather Type: You need to decide whether you want to use Full-Grain/Top-Grain leather, Split Leather, or Recycled Leather. Full-grain leather retains the natural texture and strength of the hide and is the top choice for high-end products. Split and recycled leather are more economical but have lower durability and feel. You also need to consider if you want stiff, shapable Vegetable-Tanned leather or soft, body-hugging Chrome-Tanned leather. Understanding the properties, costs, and care requirements of different leathers will directly affect your product descriptions and customer service. Experienced manufacturers can provide suggestions based on your design drawings.

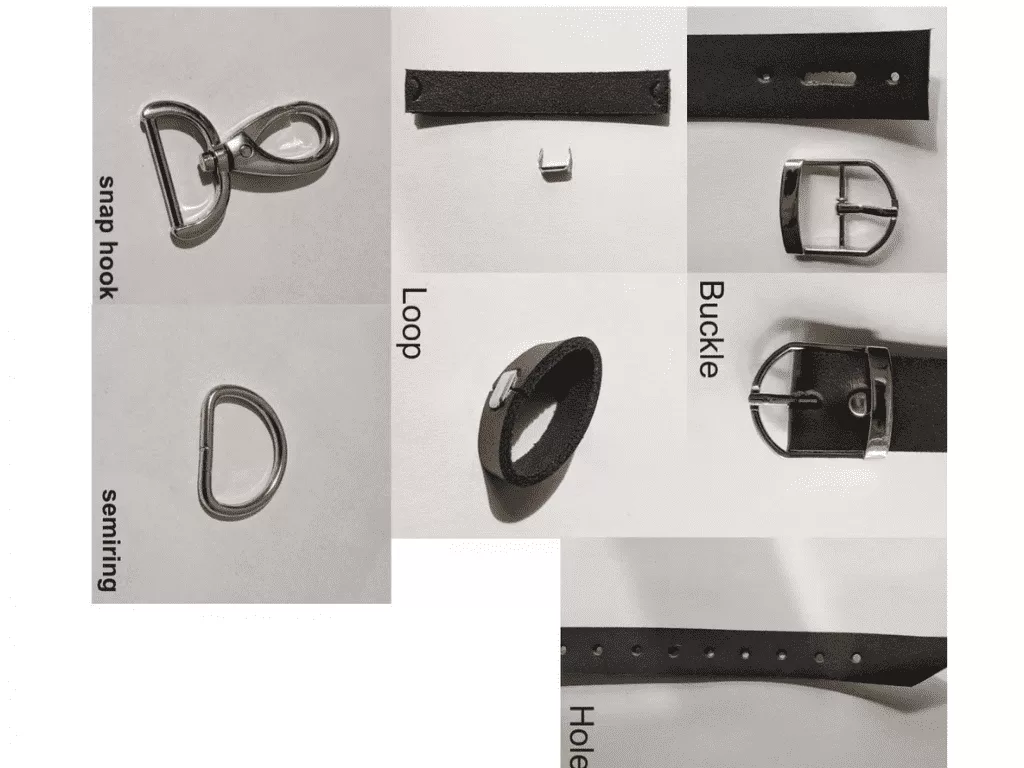

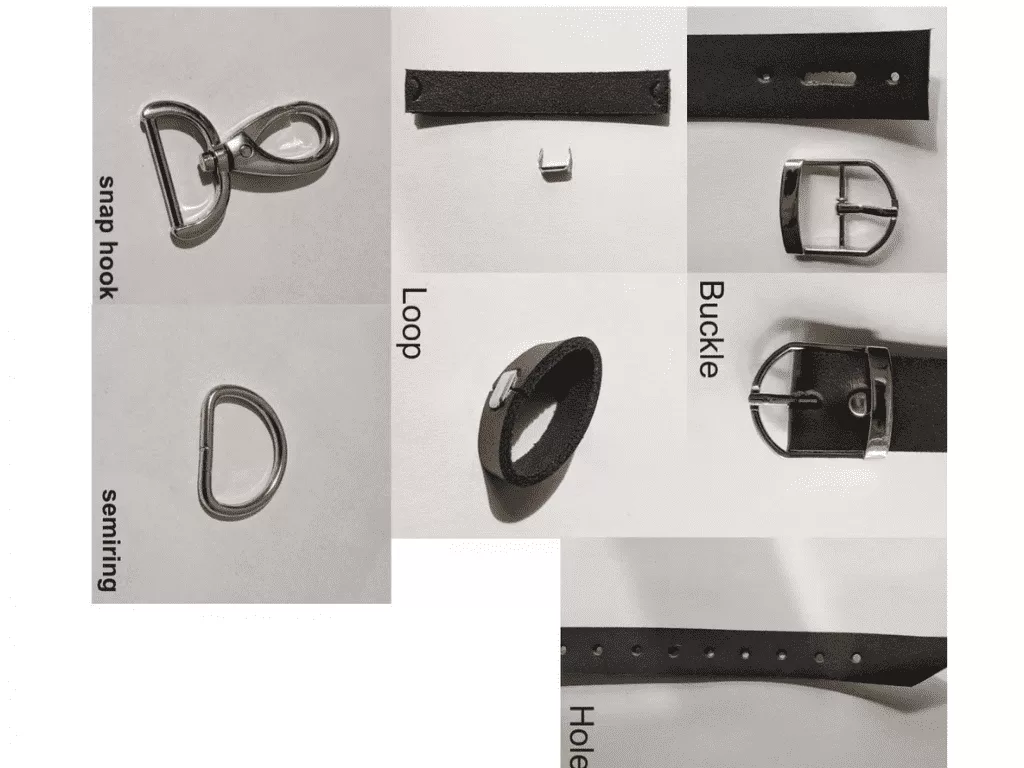

Hardware: Hardware is the soul of a leather product and is critical for both strength and safety. You must be clear about your hardware material requirements. Stainless steel is durable and anti-allergenic, but the price is very high, with mold costs being the most expensive part. Pure brass has a great feel and will develop a patina over time. Alloy is more cost-effective and offers more variety. The mold price for alloy is also lower than the other two, and it comes in a wider selection of plating colors.

Budget and Production Volume

Before starting production, you can evaluate your potential sales by looking at your competitors. Competitors can provide a lot of useful information, including pricing for products of the same quality. With this, you can calculate your product’s cost and present that cost plan to a manufacturer. A good manufacturer will provide a suitable solution based on your design and budget, which can significantly reduce the initial screening and communication effort. If a manufacturer can’t meet your budget, you can move on. If you consult with more than three manufacturers and still can’t meet your budget, you may need to increase it. Forcing a lower budget will only lead to one result: the final product not matching the design or using cheaper materials. While this might save costs, the product quality becomes a major risk.

| Action | Key Takeaway |

|---|---|

| Evaluate Sales | Look at competitors to estimate potential sales and pricing for similar quality products. |

| Calculate Your Cost | Use competitor pricing to determine a realistic cost plan for your product. |

| Consult Manufacturers | Present your design and budget to manufacturers. A good one will provide a suitable solution that fits your needs. |

| Be Realistic | If multiple manufacturers cannot meet your budget, you may need to increase it. Forcing a lower budget often results in poor quality or using cheaper materials. |

Manufacturer’s Craftsmanship Level

1. The Ability to Understand Drawings When you’ve meticulously designed a new series, if a factory has no experience producing that type of product, they may not understand the design intent. It could take several rounds of communication to grasp the effect you want.

2. Communication Skills When choosing a manufacturer, having an English-speaking sales representative is a basic requirement. However, many salespeople don’t have hands-on production knowledge. This can make communication complicated and time-consuming, as many details about the process can’t be confirmed right away. A lack of familiarity with various materials can make communication even more difficult, potentially leading to a sample that isn’t made correctly.

3. The Ability to Provide High-Quality Solutions For example, a client of mine once handcrafted a paddle. It was very rough and felt hard. Both sides of the paddle used a spongy foam. This meant the user experience was not very intense, and a hard strike would just feel like a gentle tap. When we opened up the sample, we saw two very fluffy sponges inside, which were not suitable for long-term use. We suggested replacing the fluffy sponge inside with a fiberboard and adding a high-density sponge to the other side. The final product had one hard side with strong support and one side with a soft, elastic foam. The client was very satisfied because it provided two different user experiences.

In my 8 years of experience, I often encounter designs that are not physically possible to produce. A design is a two-dimensional drawing, but the finished product must follow the laws of physics. An experienced factory will not blindly follow a drawing; they will provide more suitable suggestions. For example, they might suggest what kind of padding to add to a reinforcement for a better effect. They will also consider practical use and durability, which requires long-term experience. A factory without relevant experience will not be able to consider these details.

Tang Leather Goods Factory

Our factory has been involved in the production of BDSM leather goods since 2013. We have in-depth collaborations with UPKO in China and other niche designers. We specialize in both high-end and fully custom products. For custom products, we have a low minimum order quantity of just 50 pieces per style. We have set a low entry barrier because we want to give clients a chance to work with us. Perhaps we are the BDSM leather goods supplier you have been looking for.

FAQ:

1. How can I ensure my design will be made correctly? We will create a mock-up using paper or PU and send you photos for confirmation. If approved, we will then proceed with a sample using the correct materials.

2. How do I get a quote? We can provide a rough quote based on your drawings. For an accurate quote, we’ll need to complete a sample. However, based on our experience, the prices won’t differ much.

3. Do you only make genuine leather BDSM products? We can also work with Vegan leather or PU. We will apply the same craftsmanship as we would for genuine leather. With good craftsmanship, even with PU or microfiber, the product can achieve an excellent texture.

4. How much do samples cost? For small items (chokers) using our in-stock leather, we only charge a fee of $30. For larger items like whips or paddles, the cost is $85. If custom materials are needed, the fee will be based on the material cost.