I. Introduction

A woven leather handbag is a handmade item where leather strips are woven together to create a unique texture. It’s famous for being durable, beautiful, and luxurious. The design often comes from traditional weaving techniques, like the iconic Intrecciato method from the Italian luxury brand Bottega Veneta. This technique uses fine leather strips woven by hand to make a seamless grid pattern. That’s why Bottega Veneta bags are so expensive . Historically, this craft started in the mid-20th century with Italian leather artisans who applied textile ideas to leather to improve the bag’s strength and artistic value. Today, woven leather handbags are a favorite in the fashion world, not just for their unique look, but because they mix handmade craftsmanship with modern design.

The manufacturing process is important because it’s more than simple assembly. It involves many steps, from choosing raw materials to fine weaving, usually combining handwork and machines. This ensures quality and shows potential for sustainability and custom designs. In high-end brand production lines, each bag might need hours of hand weaving to make the texture even and strong. This creates rarity. Compared to machine-made products from assembly lines, woven bags rely mostly on hand weaving in the key steps. Training a beginner to become a skilled artisan takes years. It’s not just a fashion item; it’s an artwork full of the craftsman’s spirit. Its craftsmanship value is way more than the cost of the materials.

II. Material Selection and Preparation

The first step in making a woven leather handbag is carefully picking materials and tools. This directly affects the final product’s quality and look. Leather is the main material, usually cowhide, sheepskin, or calfskin. These have good flexibility and durability. Cowhide is often used for large bags because its thickness (usually 1-2 mm) can handle the tension during weaving, and its larger size allows cutting longer and more strips for weaving. Sheepskin is better for delicate small or medium bags. Sheep are smaller, so a sheepskin sheet is smaller too. Using it for big bags like shoppers or Neverfull styles isn’t practical because they’re too large, and it would cause huge waste. Woven leather bags have a lot of material loss. For environmental and sustainable reasons, many makers use leftover leather or eco-friendly tanned leather to cut down waste and impact. For example, LOEWE uses leftover leather for woven basket bags. Leftover leather needs re-dyeing to make colors uniform and textures consistent.

If it’s PU, I don’t recommend hand weaving for that effect because PU isn’t animal leather; it’s synthetic fiber. It has poor tension and elasticity, and it only comes in fixed thicknesses. Unlike real leather, you can’t shave it to different thicknesses. So, PU can be machine-woven into rolls during production and used directly for sewing.

For tools, hand weaving needs basic cutting knives, hole punchers, and weaving frames. These frames are like textile looms to fix the leather strips and keep tension even. For large-scale production, cutting strips is like cutting belts—using a splitter machine to cut the leather into equal strips. This boosts efficiency and keeps products uniform. But for real leather woven bags, machines can’t do the weaving on the bag body or handle parts. You need molds made by master craftsmen, and workers weave along the molds to make it happen.

III. Main Steps in the Manufacturing Process

Making a woven leather handbag is a multi-stage process that needs experienced artisans. It’s more time-consuming than making regular bags and tests the pattern maker’s skills.

Step 1: Design and Planning

Everything starts with design. Even if the client’s drawing is clear, with details on size, texture, and shape, we still need experienced masters to plan how to start weaving, including what molds to use for shaping. It also includes calculating the number and length of leather strips needed to maximize material use. Making a prototype is essential: use cheap materials like cardboard or fabric to test proportions and comfort. Here, faux sheepskin PU is super useful because it’s soft enough for weaving trials without wasting real leather.

Step 2: Leather Preparation and Cutting

Once the design is set, we prepare the leather. Based on the design, we shave the leather to different thicknesses or soak it in oil to make it tough enough for weaving.

We cut the whole leather sheet into even thin strips. This is key for weaving, usually done with hand tools or laser cutters to keep widths consistent. For Bottega Veneta-style Intrecciato weaving, cuts need to be precise to the millimeter because strips go through pre-cut slits to interweave. This step can take hours, especially by hand, to avoid waste.

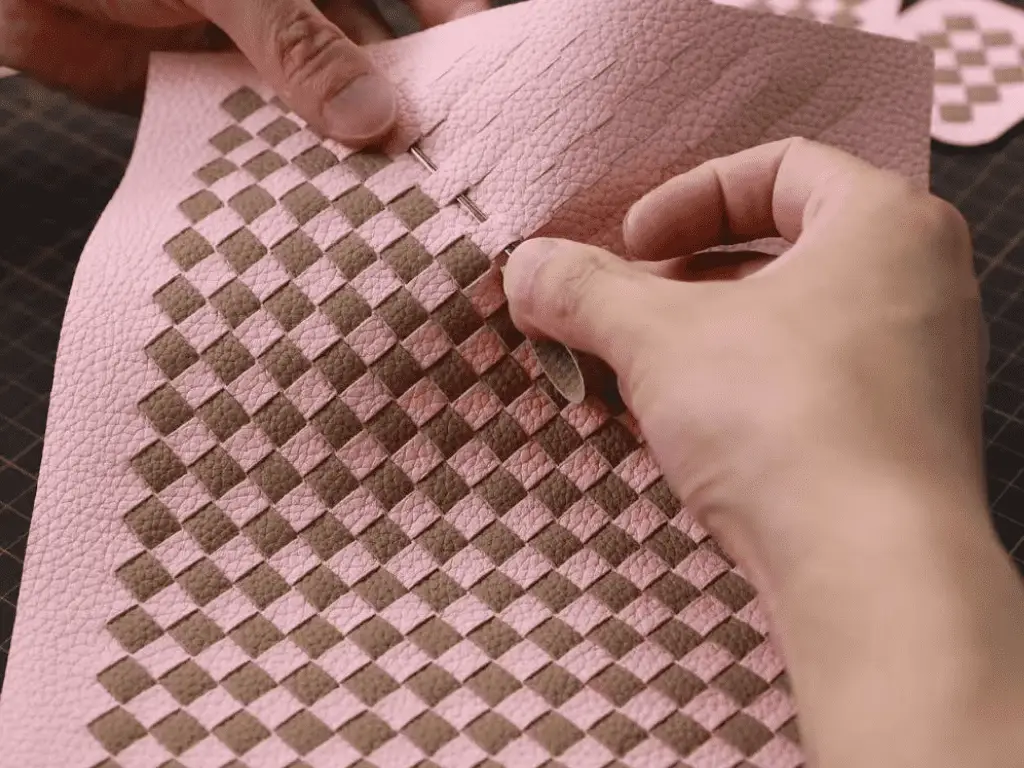

Step 3: Weaving Process

Weaving is the heart of the whole thing, usually done by hand by skilled workers. Fix the cut leather strips on a mold frame, then use interweaving methods: like plain weave (strips alternate horizontal and vertical) or basket weave (like weaving a basket). Artisans adjust tension by hand to make the texture even and tight. For example, when making a tote bag, start from the bottom and weave up to form sides and opening. This stage highlights the art of hand labor: each bag’s texture is one-of-a-kind and might take days to finish. For semi-mechanized production, machines can help with initial weaving, but final tweaks are still by hand.

Step 4: Assembly and Sewing

After weaving, we assemble. Sew the inner lining fabric into the bag, add pockets, compartments, and zippers for better function. Handles and straps are fixed with punching and sewing, using heavy sewing machines to strengthen edges and prevent unraveling. Hardware like buckles needs precise installation for symmetry and strength. This step mixes hand and machine work to make the bag’s structure solid.

Step 5: Finishing and Polishing

Finally, do the finishing: trim extra leather strips, apply waterproof wax or polish for a smooth, shiny surface. Edges might need heat pressing or hand sanding for better looks. Final checks include stretch tests to ensure the woven parts are durable.

IV. The Power of Weaving

In many styles, the handle connects to the bag body without stitches—just through weaving. This makes people worry if the bag can handle weight in real life. We put water, phones, even umbrellas—heavy stuff—in bags daily. Can a bag held together just by weaving support that? The answer is: absolutely yes.

Quality control runs through the whole process, especially at the end. In our factory, we do multiple tests: visual checks (like color consistency and texture evenness), function tests (like smooth zippers and strong handles), durability assessments, and load-bearing evaluations. Any flaws, like loose woven strips, get fixed or redone to meet high standards.

V. Conclusion

The manufacturing process of woven leather handbags, from material prep to finishing, shows the perfect mix of craftsmanship and innovation. This craft creates durable, beautiful items and passes on traditional skills. In the future, with sustainable materials and digital designs rising, this field will see more innovations, like personalized 3D weaving patterns. You can make unique patterns without a single stitch. Our factory always sticks to high-end craft ideas, creating the most unique and luxurious woven handbags for various brands.