As an overseas sales representative for leather goods, I know how complex and challenging it is to create wallets, handbags, or belts. Each leather product must showcase premium quality and durability, involving irreversible processes like cutting, stitching, and dyeing. High-quality leather can cost hundreds or even thousands of dollars per hide, and any mistake can lead to costly waste. Samples often require multiple revisions, especially for complex designs, before final approval. Starting with real leather for samples risks wasting expensive materials. That’s why I always begin with a prototype—a preliminary model made from affordable materials like canvas, cardboard, or low-cost PU leather—to test designs and processes. In this article, I’ll share why prototyping is essential for leather goods, focusing on how it saves costs, improves designs, and ensures quality.

Main Reasons

Reason 1: Saving Costs and Reducing Waste

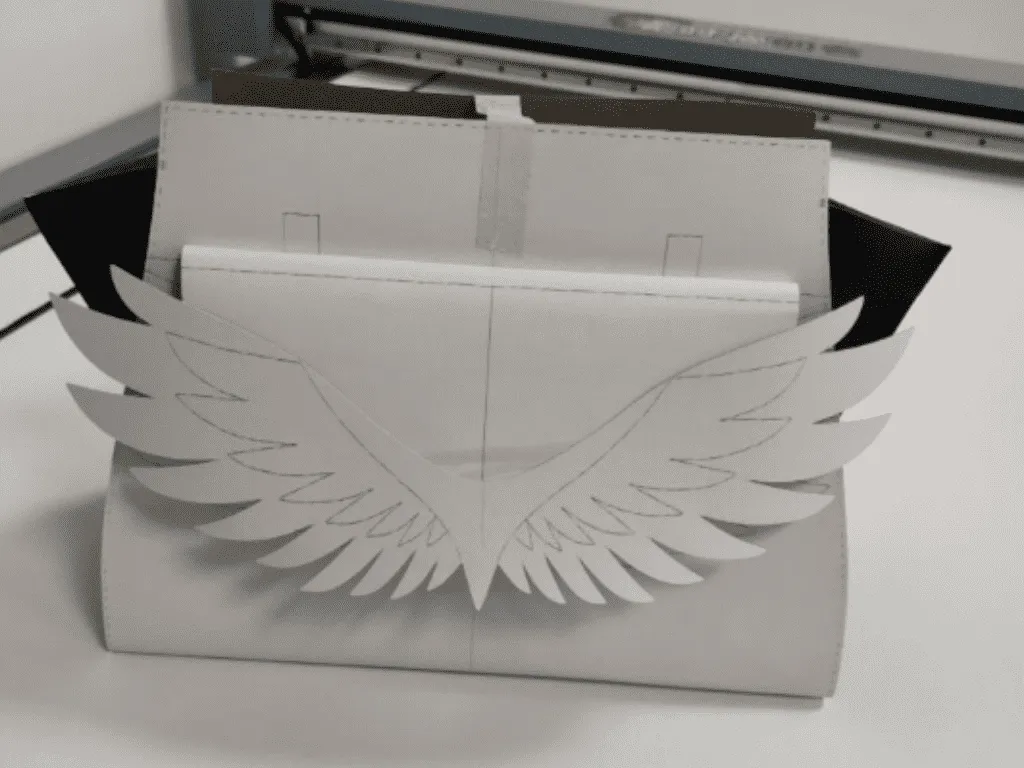

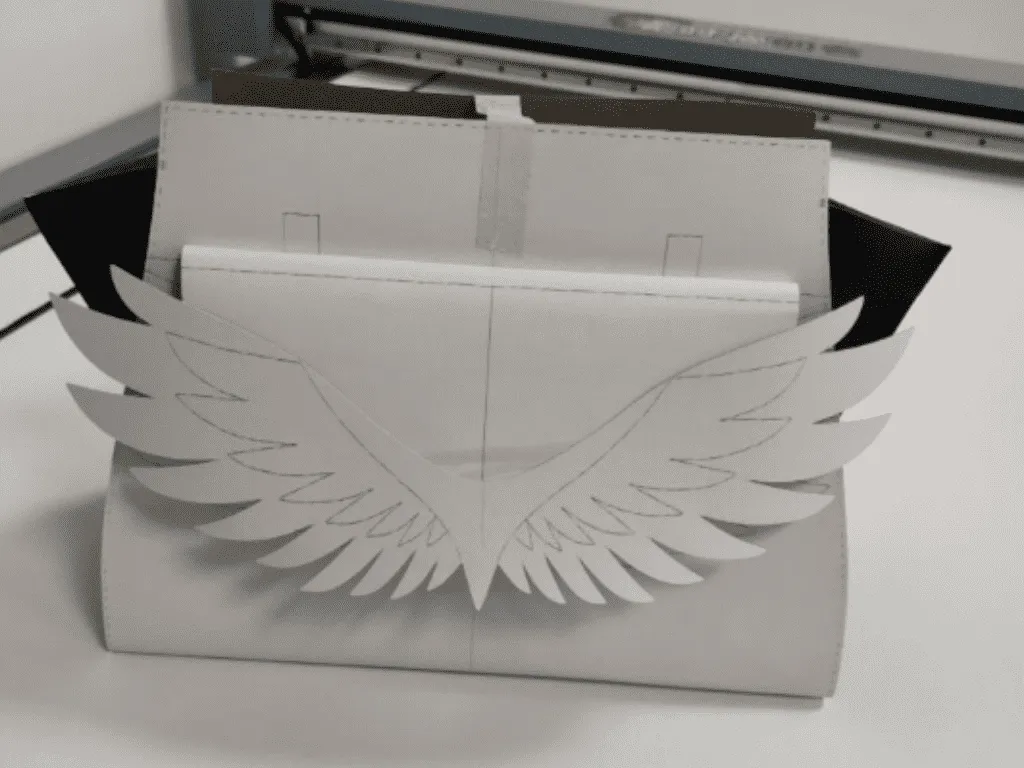

I’ve learned that leather, as a natural material, is incredibly expensive to source and process. Whether it’s cowhide, sheepskin, or rare crocodile leather, each piece represents a significant investment. Once cut or stitched incorrectly, the material is ruined, leading to financial loss. To avoid this, I use low-cost materials like cardboard or PU leather to create prototypes and test designs. For example, when a client sends a new design, I first make a basic bag shape with PU leather to adjust proportions. This process skips time-consuming steps like edge finishing or sourcing specific materials (like the exact leather color or hardware, which takes time to order). A prototype can be ready in about a week, ensuring the design is perfect before using real leather. This approach saves clients money on sample costs and significantly reduces waste, boosting cost efficiency.

Reason 2: Validating Design and Functionality

To me, leather goods are not just art—they’re practical, everyday items that must balance beauty, functionality, and ergonomics. For instance, a handbag needs to handle weight comfortably, and a wallet must have a practical card slot layout and smooth opening. However, design sketches often fail to reveal real-world issues. By creating a prototype, I get a physical model to test the design and its functionality. For example, I once made a bag prototype and noticed the body was too narrow, making it hard to reach inside for items. By this ,customer will ask adjusted the design before moving to the leather sample. Using PU leather for these tests lets me experiment without worrying about costs, ensuring the product is nearly perfect before production.

Reason 3: Saving Time and Gathering Market Feedback

While prototyping may seem like extra work, I find it actually speeds up the development process. Starting with real leather could mean weeks or months of revisions, but prototypes allow quick iterations to identify and fix issues. Beyond that, I use prototypes for market testing. For example, clients often share prototype images on social media during product launches to gather feedback from potential customers. This provides valuable material for pre-launch buzz or even crowdfunding campaigns to gauge demand. By listening to consumer feedback, I can tweak designs to better meet market needs. This not only reduces the risk of production failures but also ensures the final product aligns with customer preferences.

The Prototyping Process

My prototyping process starts with design sketches.Sample maker use hand-drawn drafts or CAD software to outline the product, then use cardboard to create paper patterns. Sample maker lays the cardboard pattern on PU leather, cuts the pieces with a utility knife, and stitches them together. This process doesn’t focus on perfect stitching or edge painting or polishing—no need to worry about bubbles or cracks in the edges. The goal of a prototype is to refine the bag’s shape and design before investing time and money in a leather sample. Some designers make drastic changes after seeing the prototype, as flat design drawings can differ greatly from the real thing. In such cases, we may create another prototype round until the client finalizes the design. Only then do we use real leather to produce the order-ready sample.

Conclusion

For me, prototyping is more than a technical step—it’s the key to ensuring the quality and success of leather goods. It saves costly materials, validates functionality, minimizes risks, and speeds up development. With tools like AI-assisted design and 3D modeling, my prototyping process is becoming even more efficient. I firmly believe that prioritizing prototypes boosts the competitiveness of my work and supports sustainable practices in the industry. Whether you’re a beginner or a seasoned artisan, I recommend treating prototyping as the foundation of innovation and success in leather goods production.