“I feel this topic is very similar to my previous article (Is handmade leather good better than Machine made?), but this one is more focused on stitching. In my eight years in this industry, many clients have asked us to create a hand-stitched version when we’re making samples, so they can compare it. This is because every brand wants to pursue the ultimate level of quality.

I’ll be honest with you. Many people believe that handmade is always better. They picture a skilled artisan sitting for hours, carefully stitching a bag, and they imagine a product full of soul and character. And in many ways, they are right. Hand stitching offers a level of durability and charm that is truly special. But in our modern world, where efficiency and perfection also matter, the story is more complex. The truth is, machines have evolved, and the art of working with them has become a craft in itself.

I want to take you on a journey to explore the real differences between hand stitching and machine stitching, and to share how we, at our factory, are combining the best of both worlds to create leather goods that are not only beautiful but also built to last a lifetime.

The Art of Hand Stitching: The Saddle Stitch

Hand stitching is often called the purest form of leather craft. The primary technique used is the saddle stitch. Its name comes from its historical use in making saddles and other horse tack—items where a stitch failure could be catastrophic.

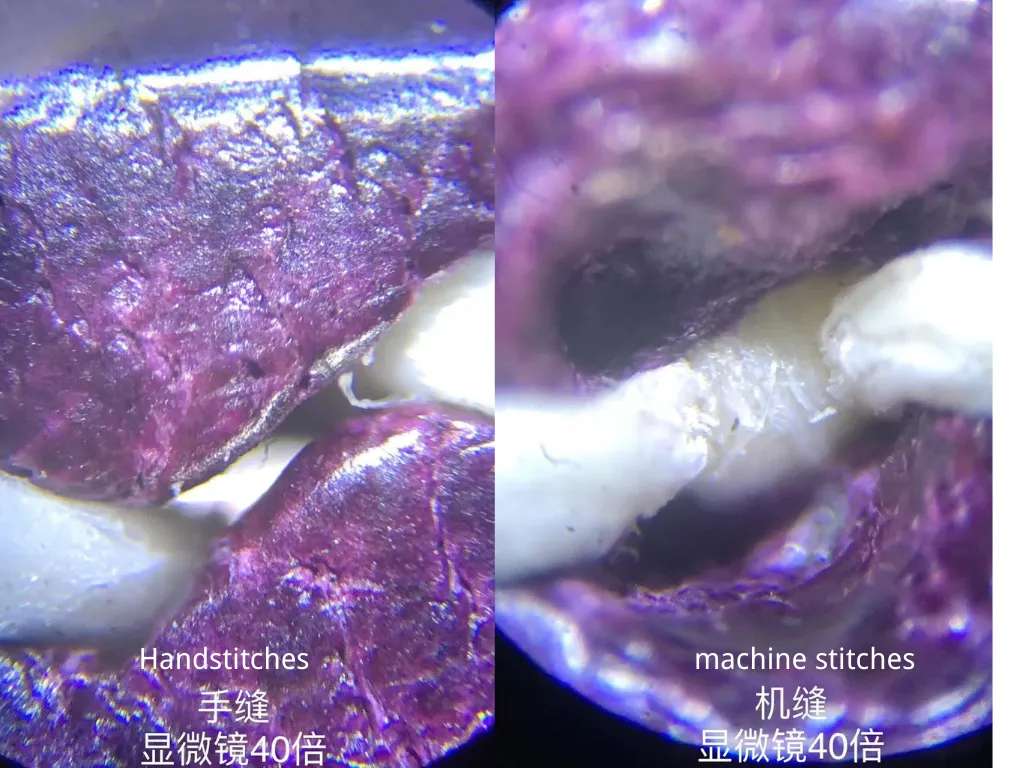

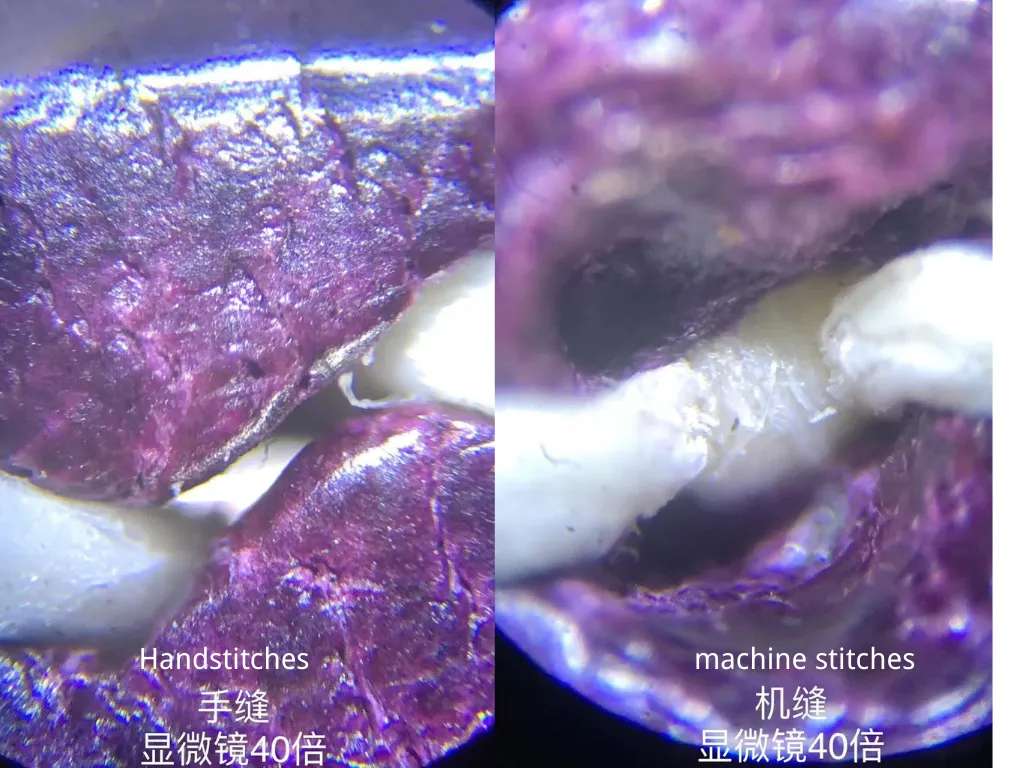

To perform a saddle stitch, an artisan uses a single piece of thread and two needles. They push both needles through the same hole, one from each side, and pull them tight. This creates a unique interlocking stitch where each thread passes through the leather twice. The result is a seam that is incredibly strong and secure

The biggest advantage of a saddle stitch is its unrivaled durability. If one of the threads breaks due to wear or a sharp object, the other thread will hold the leather together. The stitch will not unravel. You can literally cut a thread and the entire seam will stay intact, because each stitch is an independent lock. This is something that no standard sewing machine can achieve.

Beyond strength, hand stitching gives a product unique character.

Different artisans have their own unique styles, and their handcrafted work is truly one-of-a-kind. But a great result always comes down to the artisan’s experience and skill.

For less-experienced artisans, hand stitching is a real challenge. They may not have the precise control needed to keep the thread tension and stitch spacing consistent. This can lead to uneven, loose stitches that compromise both the look and durability of the finished product.

This is where things can get confusing for new buyers of handcrafted leather goods. They might see an item with sloppy, flawed stitching and be told it has “character” or a “story.” But I believe a true artisan who is passionate about their craft would never allow a flawed product to leave their workshop. They understand that every single stitch is a mark of their dedication and skill.

The Power of Machine Stitching: The Lock Stitch

In contrast, machine stitching is a marvel of modern engineering and efficiency. The most common machine stitch is the lock stitch. This method uses two separate threads: one from a spool on top and a second from a bobbin underneath. The machine’s needle pushes the top thread down, where a hook catches the bottom thread and pulls it up, locking the two threads together in the middle of the leather.

The greatest benefits of the lock stitch are speed and uniformity. A skilled machine operator can stitch an item in minutes, a process that would take a hand stitcher hours or even days. This speed is what allows factories to produce high-quality bags, wallets, and belts at a scale that makes them accessible and affordable to more people.

And this is a crucial point that many people misunderstand. The idea that a machine stitch is always inferior to a hand stitch is no longer true. A high-quality machine stitch can be incredibly strong and beautiful. It just depends on the machine and the person operating it.

It’s All About the Machine (and the Artisan Who Runs It)

The consistency of a machine stitch has a lot to do with the machine itself and the person running it. This is where the old-school idea of machine work being “soulless” falls apart. In a professional setting, operating a machine is a craft in its own right.

Not all leather sewing machines are created equal. High-end industrial machines from brands like Durkopp Adler, Pfaff, or JUKI are built with a precision and power that consumer machines simply don’t have. They are designed to stitch through multiple layers of thick leather without a single misstep. The quality of the machine is the foundation.

But the real secret is the tuning and calibration. Before starting a project, a skilled technician must adjust the machine for the specific leather, thread, and design. This process is called “tuning” or “dialing in” the machine. They adjust the tension of the top thread and the bobbin, they set the stitch length and the feed dog pressure. This is an art form. It takes years of experience to know how to get the perfect stitch on a new type of leather. This level of meticulous care ensures that the final product is flawless.So, while the machine does the stitching, a human hand and a trained eye are what make it perfect.

The Right Stitch for the Right Leather

Another misconception is that hand stitching is suitable for all leather. This is simply not true. Different leathers have different properties, and a master leatherworker knows how to choose the right technique for the material.

In the world of leatherworking, not all materials are created equal. And because of that, not all stitching methods are the best choice for every project. A great artisan knows how to match the technique to the material, a philosophy that is especially true when it comes to hand stitching versus machine stitching.

Hand stitching is most often used with leathers that have a smooth, flat surface and a solid, firm feel. Think of leathers like vegetable-tanned leather, shell cordovan, or buffalo hide. These materials are perfect canvases for handwork. The stitches are bold and visible against the even surface, and the thicker thread—usually a waxed thread—adds a strong, almost vintage texture. This combination highlights the unique, personal touch of the artisan and gives the finished product a rugged, classic style.

But what about softer leathers with a lot of natural texture? For example, a classic Hermès Togo leather has a very distinct grain. When you use hand stitching on a textured leather like this, the unique quality of the stitch gets lost. The beautiful diagonal slant and the careful tension are hidden by the leather’s natural texture. It takes a huge amount of time and effort, but the finished look doesn’t truly showcase the artisan’s skill. From a craftsman’s perspective, this can feel like a waste of time and an incredible waste of the artisan’s talent.

So why not use a high-end machine to complete the product instead?

In our factory, we faced this exact question. We saw a lot of brands chasing after expensive European machines like Durkopp, believing they were the only path to high quality. But we chose a different route. We decided to use Golden Wheel sewing machines, made by the Taiwanese company CHEE SIANG, which has been in the business since 1995.

Our choice was not a compromise. It was a strategic decision. We have found that a high-end machine, when properly set up, can produce a stitch that is just as good as, and in many cases even better than, a hand stitch on certain leathers. We call this process “tuning” the machine, and it’s a skill that takes years of practice to master.

With nearly 30 years of history, Golden Wheel machines have proven their reliability and precision. For our mid- to high-end clients, whose products often use a variety of leather types, our machines give us the perfect balance of efficiency and flawless quality.

For large-batch production, we have to consider time and cost. It would be unrealistic and unsustainable to hand stitch every single bag, especially when the leather’s texture would hide the beauty of the stitch anyway. By using our high-end machines, we can deliver a product that has perfectly consistent stitching, a clean modern look, and a price that makes sense for our clients.

Our factory’s approach is not about choosing one method over the other. It’s about a deep understanding of the craft, the materials, and the tools. We believe that a perfect stitch is a perfect stitch, whether it comes from a needle or a machine, and the smartest choice is to use the right one at the right time.

The Hybrid Approach: Combining the Best of Both Worlds

This brings me to the core of our philosophy at our factory. We don’t believe it’s a battle between hand stitching and machine stitching. We believe it’s about a strategic combination of both.

Our factory is dedicated to creating leather goods that can compete with the best in the world, and we do that by combining the best of both techniques. When a new brand comes to us with an original design, my heart races. Seeing their vision, and thinking about how to bring it to life, is my favorite part of the job.

We use hand stitching for the most crucial areas of a product. On a bag, the handle attachments and the strap anchors are the points that will bear the most stress. By using a saddle stitch in these areas, we ensure that the bag will be incredibly durable and last for years, a testament to its quality.在In some of products,we use handstitches for decoration。To give the product a unique selling point. This is how we increase the bag’s longevity and durability where it matters most.

For the main body panels, long straight seams, and other non-structural parts of a product, we use our meticulously tuned machines. This allows us to create a flawless, uniform look, while also ensuring that the final product is affordable and can be produced efficiently

We are not just a factory; we are a community of craftspeople who are passionate about leather. We believe that by combining the timeless strength of hand stitching with the modern precision of machine work, we can create leather goods that commited your satisfaction. We are confident that our products are not just well-made—they are pieces that can truly rival handmade items in both beauty and longevity.

We look forward to partnering with you to bring your unique designs to life.