Creating high-quality leather bag samples is a time-intensive process that often surprises those outside the fashion and manufacturing industries. Many wonder why producing what appears to be a single prototype requires weeks or even months of work. The answer lies in the meticulous craftsmanship, careful material selection, and iterative refinement that goes into each sample. This article explores the three primary reasons behind the lengthy sample production timeline: the multi-stage sample process, thorough raw material preparation, and the artisan’s adjustments to perfect the prototype.

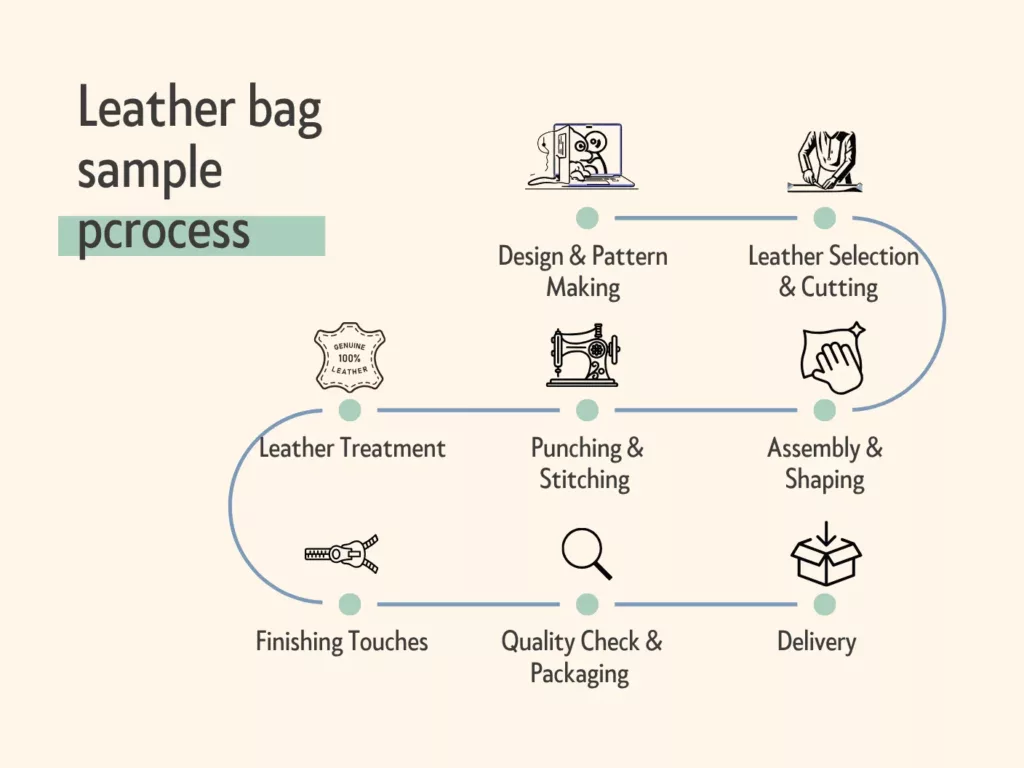

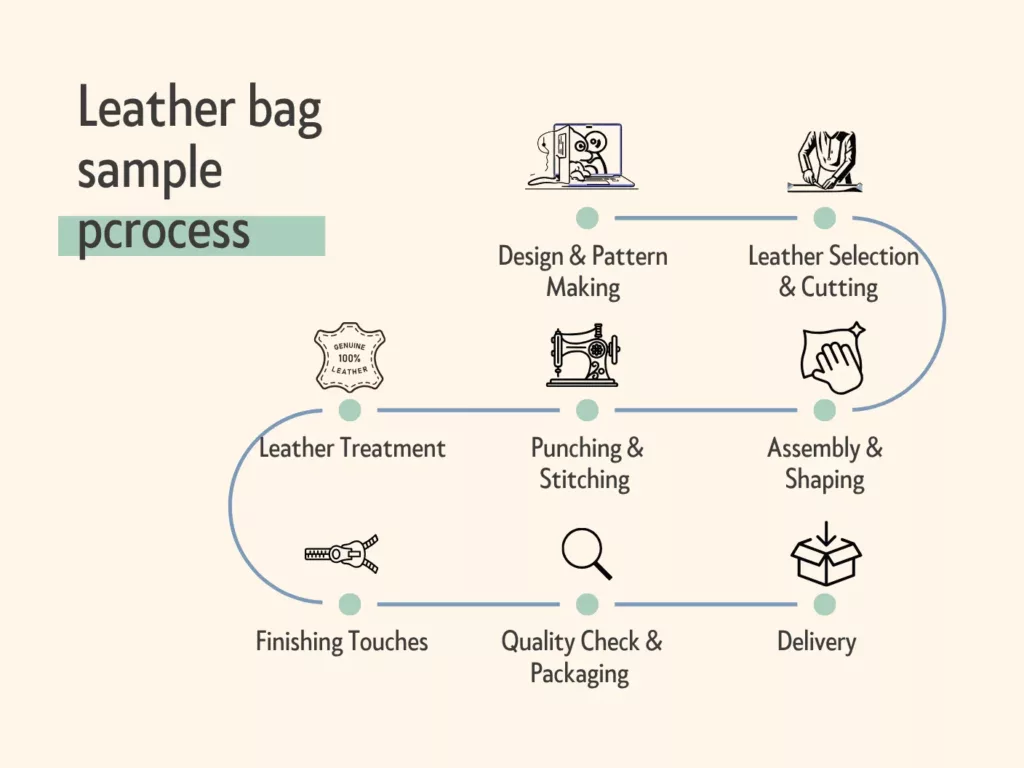

The Sample Process

Punching & Stitching

Time: 2-5 days

- Punching Holes/Installing Hardware: Use pricking irons or punches to create stitch holes and attach D-rings, buckles, and other metal fittings.

- Hand/Machine Stitching:

- Machine Stitching: Industrial sewing machines are used for efficiency, though with fewer fine details.

- Hand Stitching: The saddle-stitch method with two needles creates stronger and more refined seams.

Key Point: Stitch tension must be even, and sewing speed should not be too fast to prevent leather distortion or uneven stitching.

Assembly & Shaping

Time: 1-2 days

- Component Assembly: Sew together front/back panels, side gussets, and base pieces to form the 3D bag structure.

- Attaching Lining (if applicable): Secure the lining fabric with adhesive or stitching.

- Shaping: Use a mallet to flatten seams or insert stuffing to shape the bag naturally.

Key Point: Symmetry must be maintained during assembly to prevent the bag from appearing crooked.

Finishing Touches

Time: 0.5-1 day

- Edge Sanding: Smooth rough edges with sandpaper or a burnishing rod, then polish with edge paint.

- Surface Care: Apply conditioner or waterproof spray to enhance the leather’s luster and durability.

- Hardware Protection: Wipe metal fittings to prevent oxidation.

Key Point: Details define quality—edges and stitches must be clean and precise.

Quality Inspection & sample report

Time: 0.5 day

Steps:

- Defect Check: Inspect stitching, leather surface, and hardware for perfection, making minor corrections if needed.

- Functional Test: Load items into the bag to test weight-bearing capacity and opening/closing smoothness.

- Packaging: Place the bag in a dust bag with stuffing to maintain its shape, then box it.

- Sample report:providing sample date to customer(size,material, date,product number etc.)

Key Point: Strict quality control ensures customer satisfaction.

All the aforementioned steps and time frames are required for completing a standard sample, excluding potential unforeseen circumstances such as last-minute design/size modifications requested by clients, or defective materials that render them unusable. These uncontrollable factors often lead to sample production delays, which is quite a common occurrence in our industry.

Material Properties

- Leather:When preparing materials for samples, the first item we need to order is the leather. If the leather requested by the client is not in stock, the lead time is at least 15-20 days. For special or rare colors and types, it may take up to 25 days. The leather undergoes dozens of processes—from raw hides to dyeing, then texture finishing—before it is ready for use. You can learn about more details about leather if you move your step to this page.

- Hardware: For hardware, we generally recommend clients use readily available standard hardware for the first sample to save time and costs. Custom-designed hardware requires mold production, which incurs additional expenses ranging from $120 to $290 per mold and takes 15-25 days to complete. The entire process—from design sketching to mold production, hardware blank casting, and electroplating—involves complex craftsmanship and requires significant time.

- Printing: If the product requires printing techniques such as silk-screen or digital printing, custom artwork must be created before sending it to specialized factories for production. This typically adds another 5-7 days to the timeline.

In addition to these, other processes like sourcing specific fabric styles or laser engraving on leather also require at least one week of preparation time.

Key Takeaways:

- Leather lead time: 15-25 days (depending on rarity)

- Custom hardware: $120-$290 per mold + 15-25 days

- Printing: 5-7 days (artwork + production)

- Other specialty processes: Minimum 1 week

This detailed breakdown explains why material procurement significantly impacts the overall sample production timeline. Quality craftsmanship cannot be rushed—every step ensures the final product meets luxury

How to save time in sample stage?

With more than 20 years experience, we implement a three-phase approach to accelerate sample production while reducing costs&time.

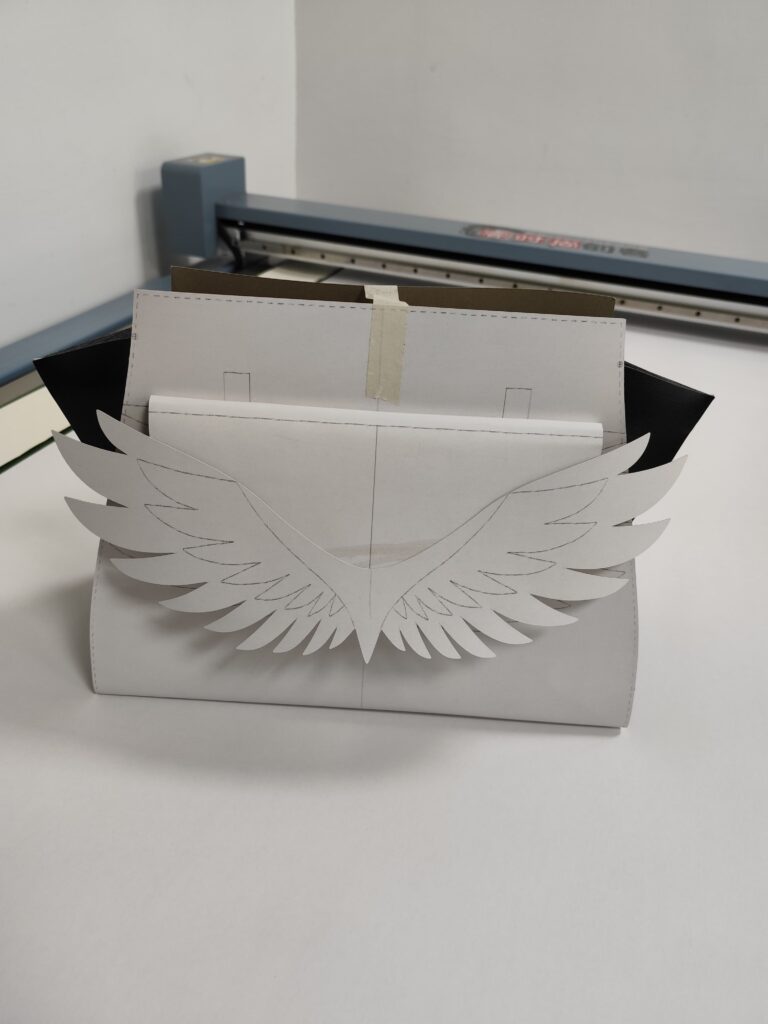

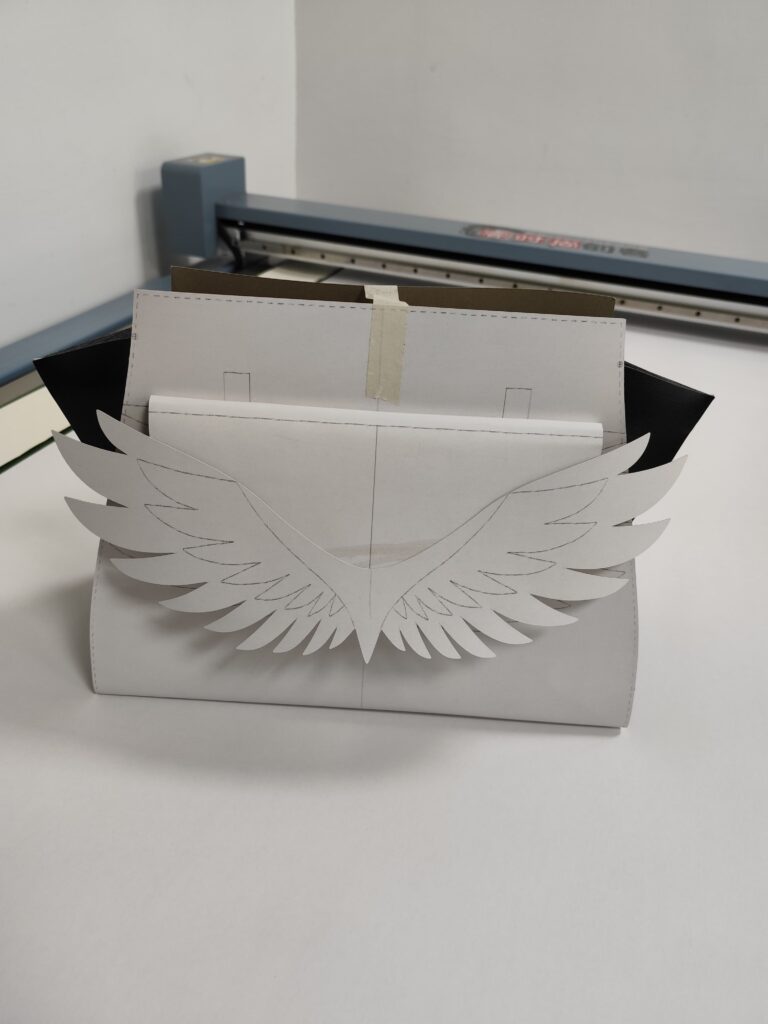

1. Prototype First, Perfect Later

- Begin with 3D models or mock-ups to validate structure and proportions.

- Focus on core functionality rather than final materials.

- Saves 5-7 days compared to traditional sampling.

2. Use Available Materials to Save Time

- Leather: Prioritize in-stock hides instead of waiting for custom orders (cuts 10-15 days lead time).

- Hardware: Use off-the-shelf components (zippers, buckles, etc.) for initial samples.

- Avoids costly custom molds and material delays.

3. Accept “80% Perfect” First Samples

- Designs vs. Reality Gap: Since sketches don’t always translate perfectly into 3D forms, an approximate sample helps identify necessary adjustments early.

- Brands Usually Modify: Most clients request changes after the first sample anyway—so investing in 100% perfect materials upfront is inefficient.

- Reduces wasted costs by 30-40% and speeds up development.

When to Use This Method?

✔ New brands testing designs

✔ Complex shape development

✔ Urgent prototype needs (e.g., trade shows)

“Speed isn’t about cutting corners—it’s about smart staging. Get the structure right first, then refine materials.”

This lean sampling process ensures faster feedback loops, lower risk, and better budget control—ideal for small factories working with evolving designs.

Upon receiving new product development requests from clients, we always prioritize sample production arrangements immediately. The sample production period typically ranges from 7 to 15 days, and while we strive to complete it as quickly as possible, we place greater emphasis on quality over speed. Quality remains our foremost consideration throughout the process.

Anyway,if you wanna have an excellent sample, please contact us and we will give you the best solution.